收藏本站在線留言網站地圖聯係婷婷91_天天艹日日艹歡(huān)迎來到江蘇雙月環保(bǎo)設(shè)備有限公司官網!

雙月攪拌·精益求精(jīng)中國攪(jiǎo)拌(bàn)裝備及傳動係統(tǒng)供應商

159952609800510-88550044

159952609800510-88550044

熱門關鍵詞: 周邊半橋全橋刮泥 中心(xīn)傳動刮泥機 立式攪拌機

攪拌裝置的設計選型與攪拌作業目(mù)的緊密結合。在設計選型時首(shǒu)先要根據工藝對攪拌作(zuò)業的目的和要求,確定攪拌器型式、電動機功率、攪拌速度,然後選擇減速機、機架、攪拌軸、軸(zhóu)封等各部件。

根據攪(jiǎo)拌介質物料的物理特性,按照工藝條件和攪拌目的,選擇攪拌器型式。

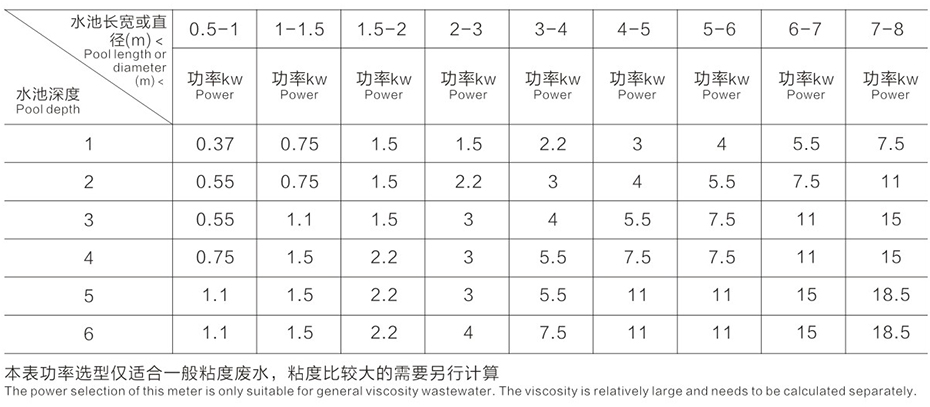

按照(zhào)所確定的攪(jiǎo)拌器(qì)型式及攪拌(bàn)器在攪拌過程中所產生的流動(dòng)狀態,工(gōng)藝對攪拌(bàn)混合時間(jiān)、沉降速度、分散度的控製要求確定電動機功率(lǜ)、攪拌(bàn)速度(dù)、攪拌器直徑。

按(àn)照電動機(jī)功率、攪拌轉速及工藝條件,從減速機選型表(biǎo)中選擇確定減速機機型。

根(gēn)據容器或池體尺寸確定(dìng)攪(jiǎo)拌器層(céng)數: 1) T殳按(àn)照池體(容器)高度/池體直徑(或長寬)比接近1:1,選(xuǎn)擇1層攪拌器;2) 當池體(容器)高度/池體直徑(jìng)(或長(zhǎng)寬)比(bǐ)大於等於1.5:1,選擇2層攪拌器;3) 當(dāng)池體(容器)高度/池體直徑(或長寬)比大於等(děng)於2.5:1,選擇3層攪拌器

攪拌流量、電機率的計算,這(zhè)是非常重要的一步:一(yī)般是根據攪拌強度的需要來確(què)定,采用計算軟件(jiàn)進行計算(suàn),具體計算時需輸入粘度值、密度、槳(jiǎng)葉層(céng)數、轉速等參數。

液體攪拌機封密型式的選擇:1) 一(yī)般情況(kuàng)下,不考慮設置密封裝置;2) 有密封要求,但密封(fēng)要求不太高的(de)場合,優先選擇四氟盤根的(de)填料箱密封;3) 嚴格(gé)密封要求的(de),可采用磁力傳動靜(jìng)密封結構,即選用磁力傳(chuán)動(驅動)攪拌機。

Choosing mixer models according to physical properties of mixing material, tech no logical conditi ons and mixing purposes.

Determining motor power, mixing speeds and mixer diameters according to determined mixer models, flow patterns during mixing and technical control requirements of mixing time, sedimentation velocity and dispersity.

Selecting determined speed reducer models from the speed reducer model table according to motor power, mixing speeds and technological conditions.

Determine the number of agitator layers according to the size of the container or pool:1)、Gen erally, accordi ng to the height of the pool body (con tainer) / the diameter of the pool body (or length and width) is close to 1:1, select a layer of mixer; 2)、When the cell body (container) height / cell body diameter (or length to width) ratio is greater than or equal to 1.5:1, select a 2-layer mixer;3)、When the cell body (container) height / cell body diameter (or length to width) ratio is greater than or equal to 2.5:1, select a 3-layer mixer

Calculation of mixing flow and motor power is a very important step:Generall, it is determined according to the need of strring intensity,and calculation software is used for calculation. In the specific calculation, parameters such as viscosity value, density, number of blade layers, and rotation speed are input.

Selection of Seal Models of L iquid Mixers:1)、Under normal circumstances, it is not considered to set the sealing device;2)、Where there is sealing requirement, but the sealing requirements are not too high, the packing box sealing of PTFE packing is preferred;3) For the strict sealing requirements, the magnetic transmission static sealing structure can be used, that is, the magnetic drive (drive) mixer is selected.

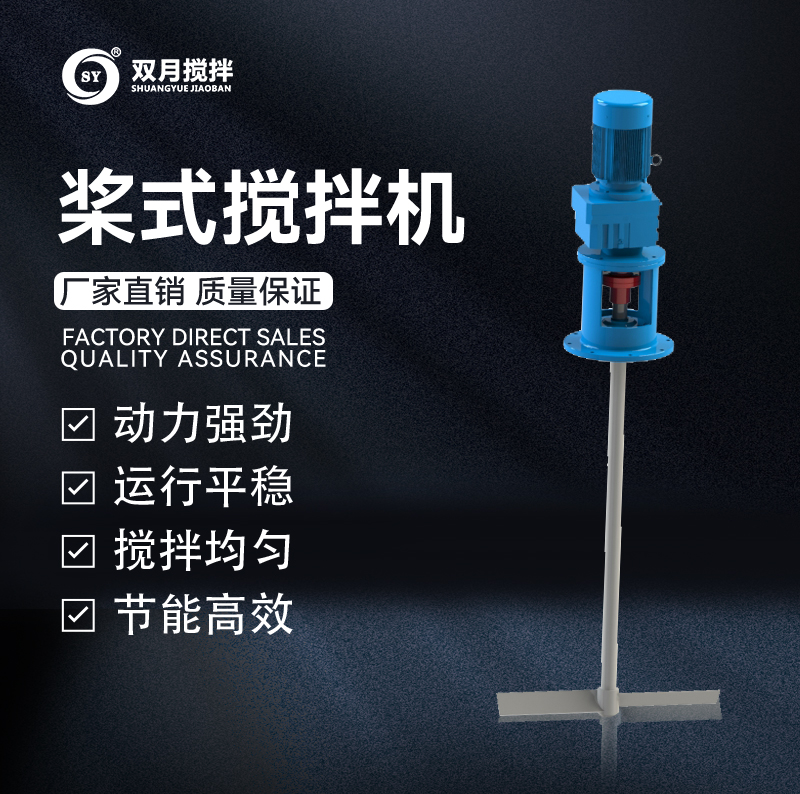

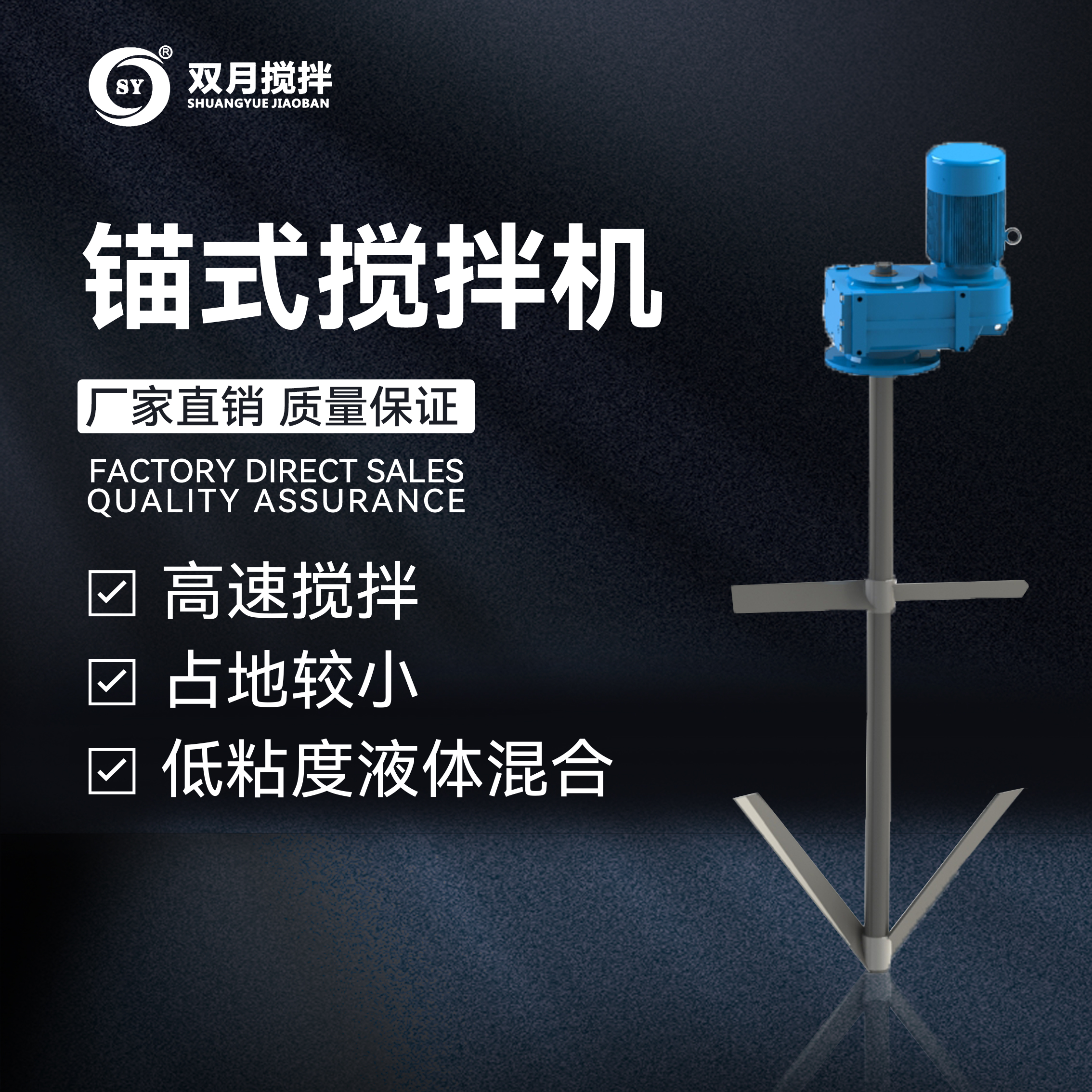

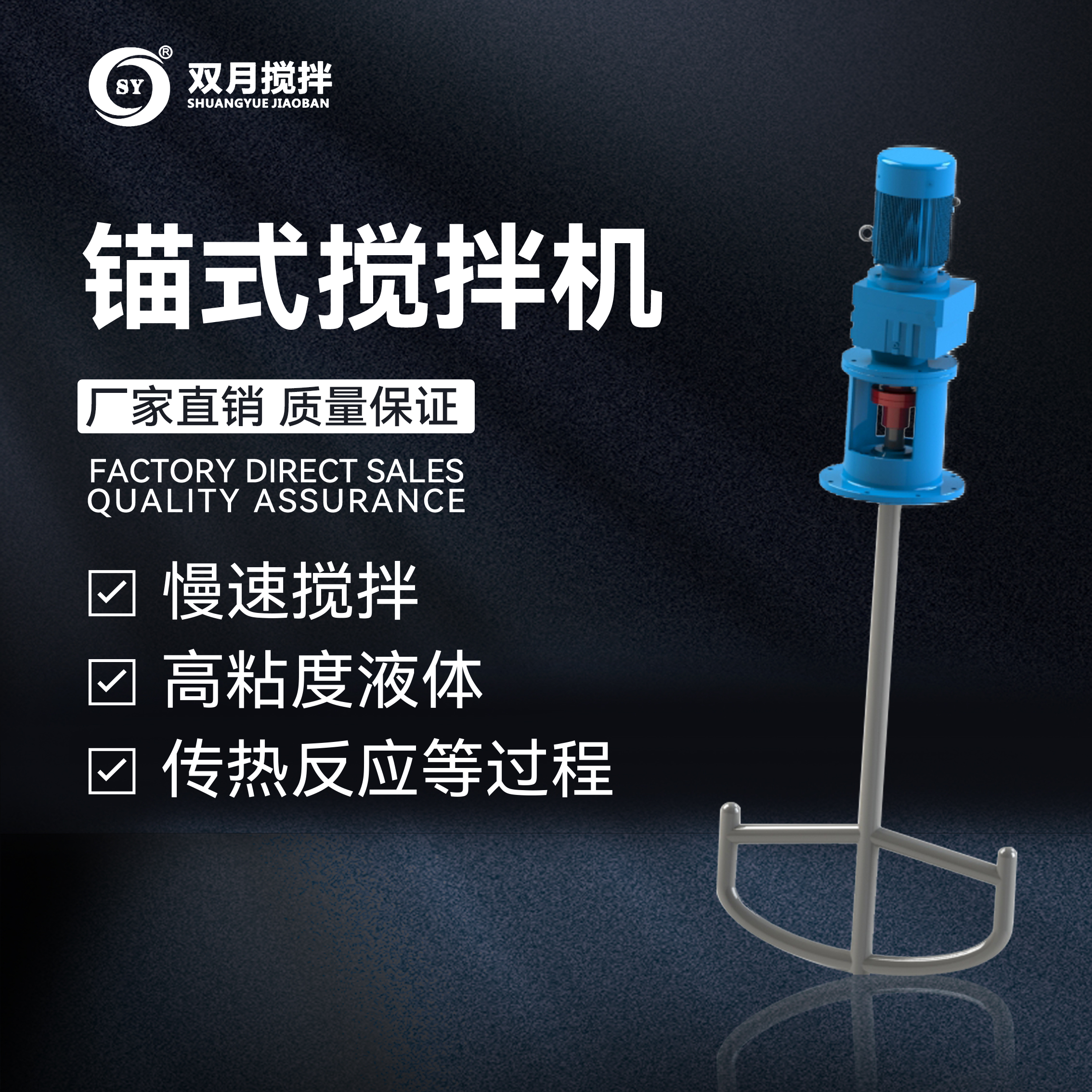

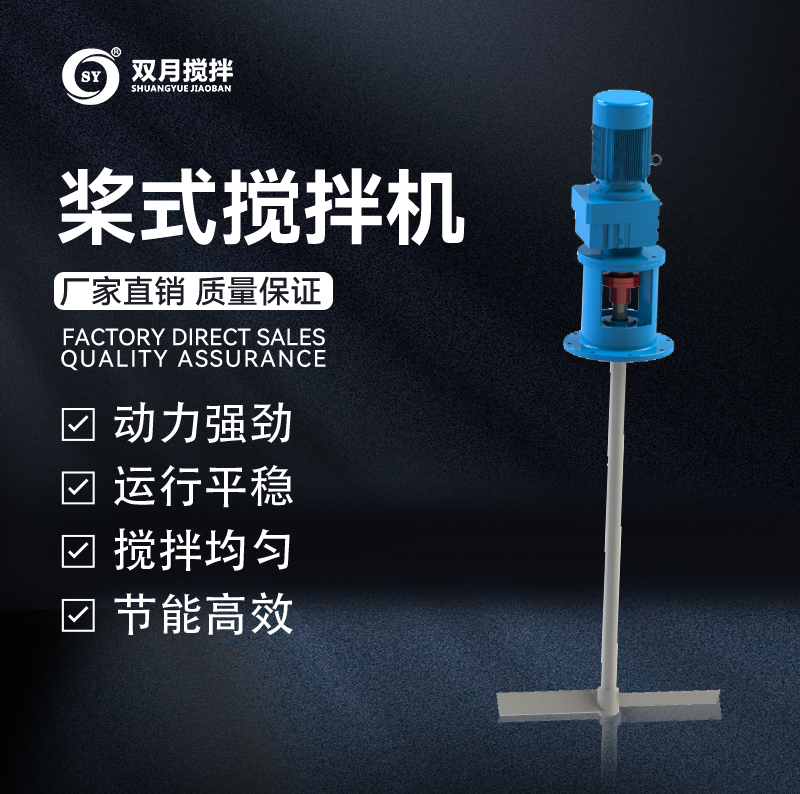

結構簡單,占地比較小,安裝方便。

適用於低粘度(dù)液體的混合、均勻、調和、溶解、傳熱或結晶(jīng)。

The structure is simple, the footprint is relatively small, and the installation is convenient.

Suitable for mixing, homogenizing, blending, dissolving, heat transfer or crystallization of low viscosity liquids.

廣泛應用於電鍍產業園、化工(gōng)廠、光伏廠、冶煉(liàn)廠、市政汙水處理廠、製藥廠等各行各業,把高效傳動攪拌的知識和水利及流態經驗(yàn)創新結合起來,讓處理的每個工段和每一滴液體實現較(jiào)佳的運行性能,致力於為(wéi)客戶創造更大(dà)價值而不懈努力!

谘詢熱線 0510-88550044

手(shǒu)機號碼: 15995260980

公司QQ: 648935210

公司郵箱:liutao@jsshuangyue.com

公司地址: 江蘇無錫市新(xīn)吳區梅村新錦路(lù)110號

全(quán)國服務熱線

全(quán)國服務熱線