收藏本站在線留言網站地圖聯係婷婷91_天天艹日日艹歡(huān)迎來到江蘇雙月環保設備有限公司官網!

雙月(yuè)攪拌·精益求精中國攪拌裝備及傳動係(xì)統供應商

159952609800510-88550044

159952609800510-88550044

熱門關鍵詞: 周邊半橋全橋刮泥 中心傳動刮泥機(jī) 立式攪拌機

化工反應釜(fǔ)攪拌機目前(qián)的選型方法(fǎ)多數是根據實踐經驗,選擇習慣應用的(de)槳型(xíng),再在常用範圍內決定攪拌(bàn)器的各種參數。也有通過小型試驗,取得數據,進行比擬(nǐ)放大的設計(jì)方法,因此反應釜的選型不(bú)是絕對的,前提是保證攪拌的效果(guǒ)。

化工反應釜攪拌機目前的選型方法多數是(shì)根據(jù)實踐經驗(yàn),選擇(zé)習慣應用的槳型,再在常用範圍內決定攪拌(bàn)器的各種(zhǒng)參數。也(yě)有通過小型試驗,取得數據,進行比擬放大的設計方法,因此反應釜的選型不是(shì)絕對的,前提是保證攪拌的效果。不論哪種做法,都離不(bú)開最初(chū)的根據攪拌目的來選擇反應釜攪(jiǎo)拌器類型這一(yī)步。所以一個完整拌(bàn)目的來選擇反應釜攪拌器類型這一步。所以一(yī)個完整的選型方案必須滿足經濟與安全的要求,根據具體工況最後確定最(zuì)佳方(fāng)案。

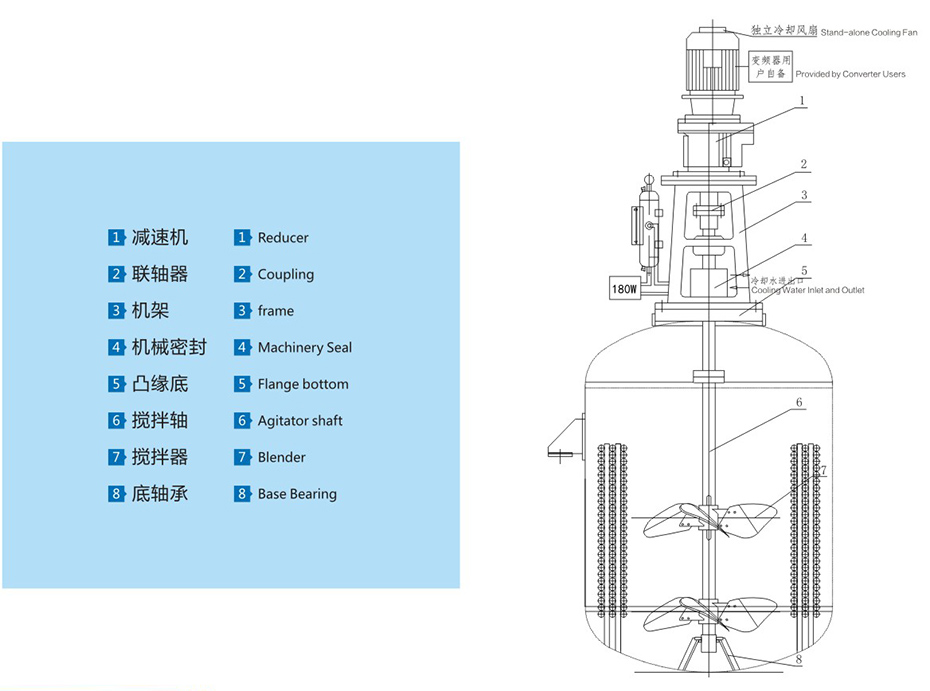

1、按反(fǎn)應(yīng)釜槳葉攪拌結構分為平葉、斜(折(shé))葉、彎葉、螺旋麵葉式攪拌器。槳式、渦輪式攪(jiǎo)拌器都有平(píng)葉和斜葉結構;推進式、螺杆(gǎn)式(shì)和螺帶式的槳葉為螺旋麵葉結構。根據安裝要求又可(kě)分為整體式和剖分式,便於把攪拌器直接固定在攪拌(bàn)軸(zhóu).上而不用拆除聯軸(zhóu)器等其(qí)他部件(jiàn)。

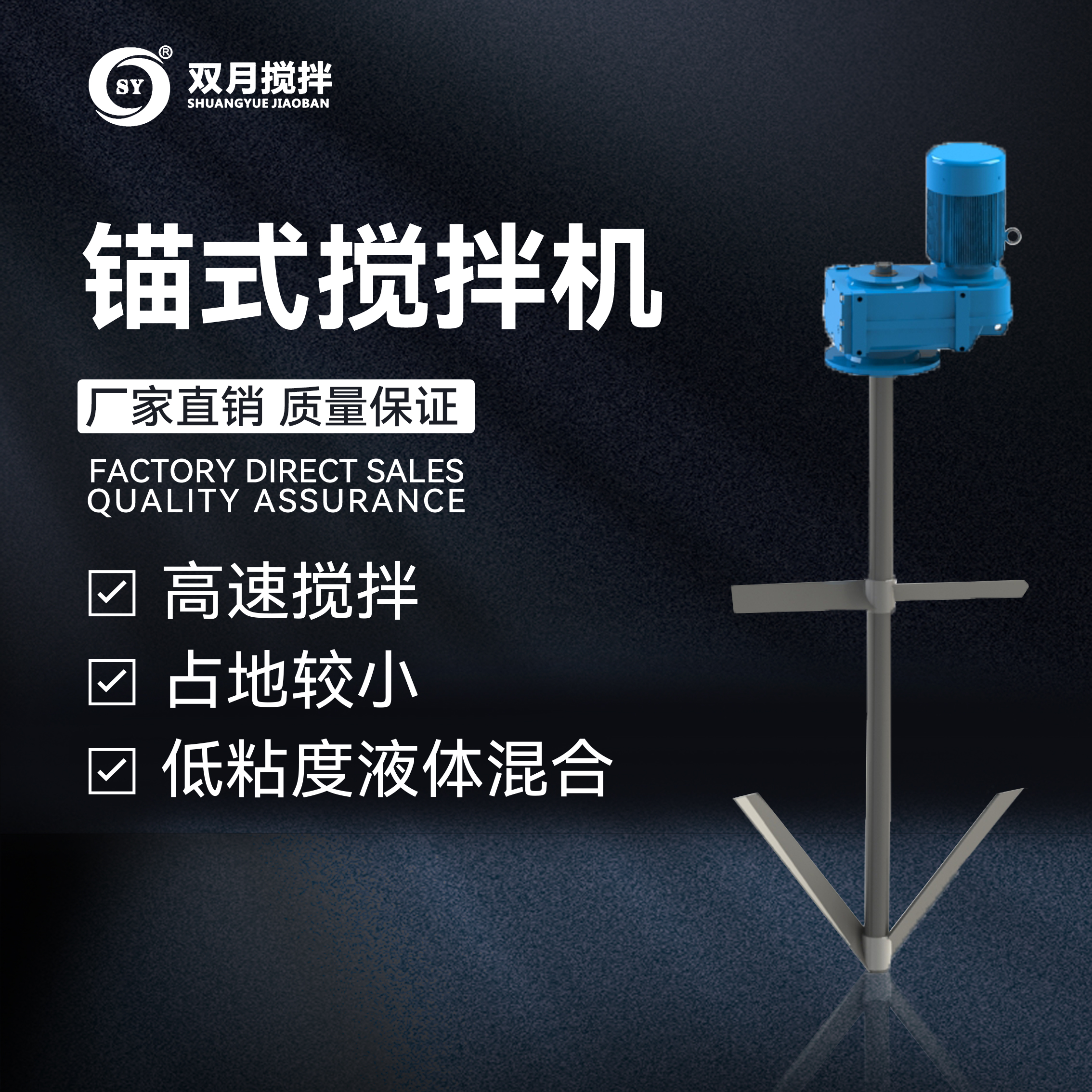

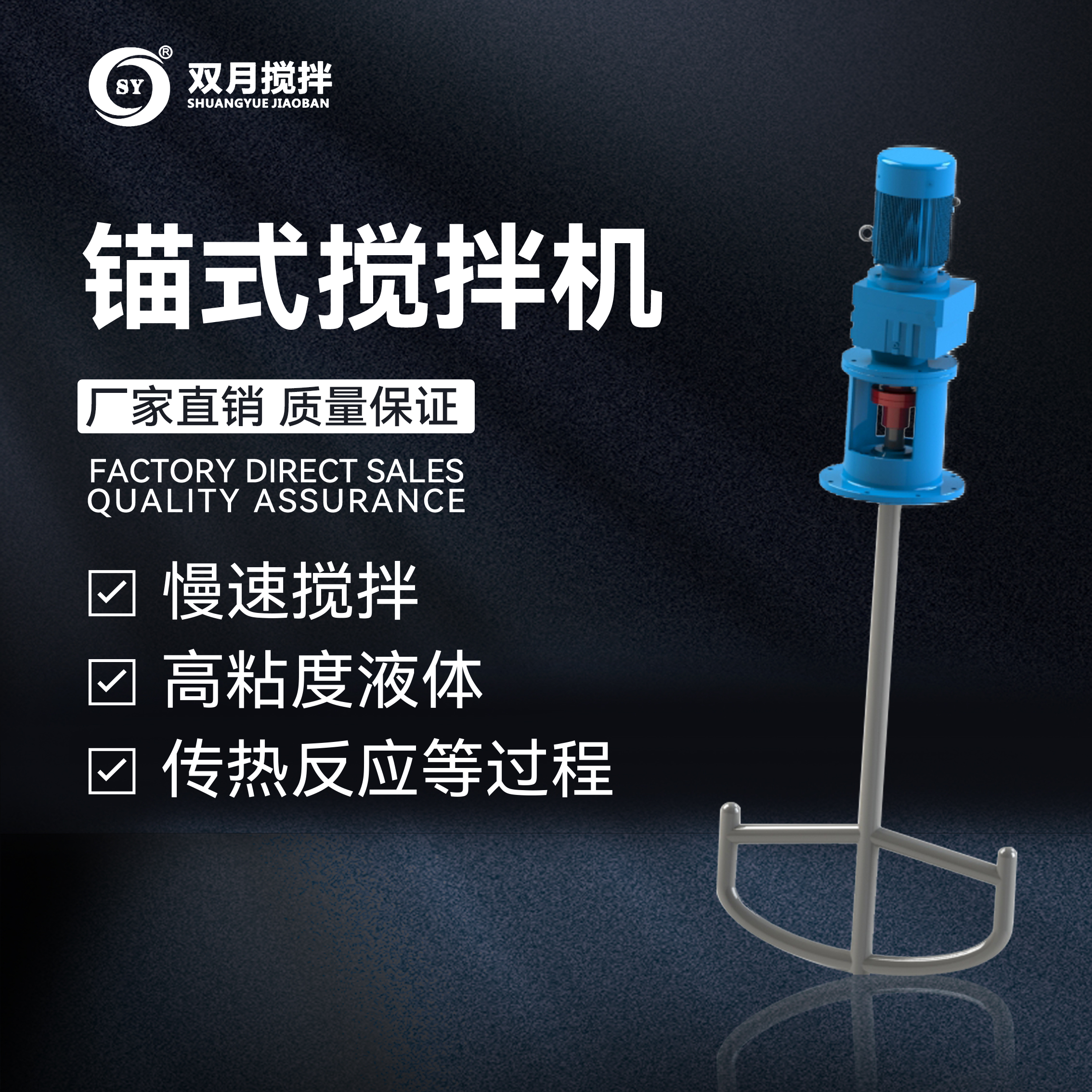

2、按(àn)反應釜攪拌器的用途分為低黏流體用攪拌器、高黏流體用攪拌器。用於低黏流體的攪拌器有:推進式、槳式、三葉後完式等。用(yòng)於高黏流體的攪拌器有:錨(máo)式、框式、鋸齒圓盤式、螺旋槳式、螺帶式等。

3、除此之外(wài),化工反應釜對於密封(fēng)則也是相當嚴格(gé)的,有(yǒu)常規單端麵機封,雙端麵機封,填料密封,根據不同的場合選擇合適的密封方式才是最佳選型。

Most of the current selection methods of the reactor agitator are based on practical experience, selecting the paddle type that is customarily applied, and then determining various parameters of the agitator within the usual range. There are also design methods that use small experiments to obtain data and perform comparative amplification.Therefore, the selection of the reactor is not absolute, provided that the stirring effect is ensured. Either way, the initial step of selecting the type of reactor stirrer based on the purpose of mixing is indispensable.Therefore, a complete selection plan must meet economic and safety requirements, and finalize the best solution according to the specific working conditions.

1. According to the mixing structures of reactor blades, the mixers are divided into flat-blade, in dined (folded)-blade, curved-blade and helicoids-blade mixtures. Paddle and turbine mixers have flat-blade and inclined-blade structures. Impeller-type, crew-type and spiral ribbon-type blades are a helicoids-blade structure. According to installation requirements, mixers can be divided into an integral type and a split type so that it is easy to be directly fastened on the mixing shaft and doesn't need to disma ntle other parts in cludi ng couplings.

2. According to purposes of reactor mixers, they can be divided into mixers for low-viscosity fluids and mixers for high-viscosity fluids. The mixers for low-viscosity fluids in elude impeller-type, blade-type, open turbine-type, disc turbine-type, Brumagin-type, plate and frame blade-type and three-backward bent type mixers. The mixers for high-viscosity fluids in elude an chor-type, frame-type, jagged disc-type, propeller-type and spiral ribbon-type mixers.

3. In addition, chemical reactors have a strict requirement of sealing.There are general single-end face mechanical seals, double-end face mechanical seals and packing seals. It is the best model selection to choose a proper sealing method according to different scenarioses.

適用於石油、化工、醫約、冶金、科研、大專院(yuàn)校等部門進行高溫、高壓的化(huà)學反應試驗,用來(lái)完成水解、中和、結晶、蒸懈(xiè)、蒸發、儲存、氫化、炷化、聚合(hé)、縮合、加熱(rè)混配、恒溫反(fǎn)應等工藝過程,對(duì)粘(zhān)稠和顆粒的物質均能達到高攪拌的效果。

It is suitable for petroleum, chemical, pharmaceutical, metallurgical,scientific research, colleges and other departments to carry out high temperature and high pressure chemical reaction tests for hydrolysis,neutralization, crystallization, distillation, evaporation, storage, hydrogenation, alkylation, polymerization, condensation. The process of heating and mixing, constant temperature reaction, etc., can achieve high stirring effect on viscous and granular materials.

廣泛應用於電鍍產業園、化工廠、光伏廠、冶煉廠、市政汙水處(chù)理廠、製藥廠等各行各業,把高效傳動攪拌的知識和水利(lì)及流態經(jīng)驗創(chuàng)新(xīn)結合起來,讓(ràng)處理的每個工段和每一滴液體實現較佳的運(yùn)行性能,致力於為客戶創造更大價值而(ér)不懈努力!

谘詢熱線 0510-88550044

手機號碼: 15995260980

公(gōng)司(sī)QQ: 648935210

公(gōng)司郵箱:liutao@jsshuangyue.com

公司地址: 江蘇無錫市(shì)新吳區梅村新錦路110號

全(quán)國服務熱線

全(quán)國服務熱線